How does the high-strength structural design of fumigation-free wooden boxes ensure the safety and stability of heavy equipment during long-distance transportation?

Release Time : 2026-01-01

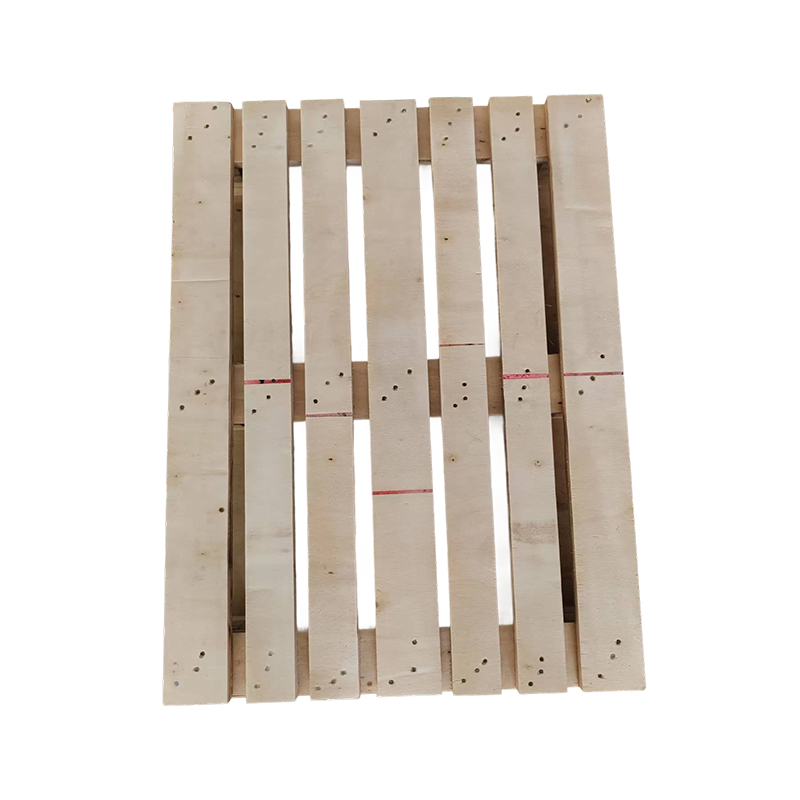

In the globalized supply chain system, the cross-border transportation of heavy machinery, precision instruments, or large industrial components places stringent demands on packaging: it must withstand multiple mechanical challenges such as sea turbulence, land transport vibrations, and lifting impacts, while also meeting international phytosanitary standards to avoid being returned or destroyed due to pests carried by the wooden packaging. Traditional solid wood crates, while strong, require high-temperature fumigation, a cumbersome process that carries the risk of cracking. Fumigation-free wooden boxes—using plywood, oriented strand board (OSB), or engineered wood as core materials—achieve load-bearing and impact resistance comparable to or even surpassing traditional wooden crates through scientific structural design and engineered reinforcement methods, without the need for fumigation, becoming a reliable "armor" for the cross-border transportation of heavy equipment.

1. Composite Board Substrate: A Dual Guarantee of High Strength and Dimensional Stability

Fumigation-free wooden boxes primarily utilize plywood, made from multiple layers of rotary-cut veneers bonded together by hot pressing. Its cross-grain structure effectively counteracts the natural anisotropy of wood, mitigating its tendency to warp. Compared to solid wood, plywood exhibits more uniform internal stress distribution, making it less prone to warping and cracking due to temperature and humidity changes. Furthermore, its static bending strength and modulus of elasticity are optimized, allowing it to withstand concentrated loads from equipment weighing several tons. Some high-end applications even employ OSB or LVL, further enhancing bending and shear resistance, providing a sturdy base for heavy equipment.

2. Framed Skeleton Structure: Key to Efficient Force Transfer

Simply relying on the box panels is insufficient to withstand complex transport loads. High-quality fumigation-free wooden boxes generally employ a composite structure of "outer frame + internal support": the main load-bearing frame is constructed from hardwood or LVL timber with dimensions of 40×60mm or larger, with the box panels serving only as the enclosure surface layer. This "beam-column system" evenly distributes the equipment weight throughout the entire box via bottom support beams, creating a stable force transmission path during lifting and stacking. Internal transverse partitions, corner reinforcement blocks, and central support columns effectively suppress box twisting and panel bulging, ensuring no deformation under conditions such as forklift insertion and container stacking.

3. Scientific Connection Technology: End-to-End Reinforcement from Bolts to Metal Corner Guards

The connection method directly determines the overall structural integrity. The fumigation-free wooden box abandons traditional iron nails, widely using self-tapping screws, countersunk screws, or special wood screws for plate-to-frame and frame-to-frame connections, providing strong interlocking force and controllable pre-tightening. Galvanized steel corner guards, edge banding strips, or U-shaped channel steel are added to key load-bearing areas to prevent localized crushing. The bottom pallet is often designed with a double crossbeam or multi-longitudinal beam structure and pre-drilled standard forklift holes to ensure smooth loading and unloading. All metal parts are rust-proofed to withstand the high salt spray environment of marine environments.

4. Customized Lining and Cushioning Systems: Body-to-Body Protection for Equipment

A sturdy box is just the foundation; securing the equipment is key. Depending on the equipment's center of gravity and shape, the interior can be customized with EPE pearl cotton, EPS foam, or wooden card slots for a "tailor-made" wrapping. Heavy equipment often uses a double-secured method of steel strapping and wooden wedges to completely eliminate the risk of displacement during transport. For high-value precision instruments, shock-absorbing brackets or air column bags can be integrated to absorb high-frequency vibration energy and prevent micron-level damage.

5. Standardization and Traceability: Ensuring Global Logistics Compatibility

Fumigation-free wooden boxes are clearly marked with IPPC fumigation-free markings, load-bearing capacity, and lifting direction information, facilitating rapid identification and operation at global logistics nodes. Some manufacturers also provide structural strength calculations and drop test reports, giving customers peace of mind.

The high strength of fumigation-free wooden boxes does not come from the advantages of a single material, but from the integrated system of materials, structure, connections, and lining systems. It redefines the "wooden crate" with an engineering mindset—no longer a crude, temporary package, but a mobile fortress tailored for heavy equipment. In the era of global trade that emphasizes both efficiency and compliance, this intelligent packaging solution, which is both fumigation-free and can withstand long journeys, is becoming an indispensable "invisible guardian" for high-end manufacturing going global.

1. Composite Board Substrate: A Dual Guarantee of High Strength and Dimensional Stability

Fumigation-free wooden boxes primarily utilize plywood, made from multiple layers of rotary-cut veneers bonded together by hot pressing. Its cross-grain structure effectively counteracts the natural anisotropy of wood, mitigating its tendency to warp. Compared to solid wood, plywood exhibits more uniform internal stress distribution, making it less prone to warping and cracking due to temperature and humidity changes. Furthermore, its static bending strength and modulus of elasticity are optimized, allowing it to withstand concentrated loads from equipment weighing several tons. Some high-end applications even employ OSB or LVL, further enhancing bending and shear resistance, providing a sturdy base for heavy equipment.

2. Framed Skeleton Structure: Key to Efficient Force Transfer

Simply relying on the box panels is insufficient to withstand complex transport loads. High-quality fumigation-free wooden boxes generally employ a composite structure of "outer frame + internal support": the main load-bearing frame is constructed from hardwood or LVL timber with dimensions of 40×60mm or larger, with the box panels serving only as the enclosure surface layer. This "beam-column system" evenly distributes the equipment weight throughout the entire box via bottom support beams, creating a stable force transmission path during lifting and stacking. Internal transverse partitions, corner reinforcement blocks, and central support columns effectively suppress box twisting and panel bulging, ensuring no deformation under conditions such as forklift insertion and container stacking.

3. Scientific Connection Technology: End-to-End Reinforcement from Bolts to Metal Corner Guards

The connection method directly determines the overall structural integrity. The fumigation-free wooden box abandons traditional iron nails, widely using self-tapping screws, countersunk screws, or special wood screws for plate-to-frame and frame-to-frame connections, providing strong interlocking force and controllable pre-tightening. Galvanized steel corner guards, edge banding strips, or U-shaped channel steel are added to key load-bearing areas to prevent localized crushing. The bottom pallet is often designed with a double crossbeam or multi-longitudinal beam structure and pre-drilled standard forklift holes to ensure smooth loading and unloading. All metal parts are rust-proofed to withstand the high salt spray environment of marine environments.

4. Customized Lining and Cushioning Systems: Body-to-Body Protection for Equipment

A sturdy box is just the foundation; securing the equipment is key. Depending on the equipment's center of gravity and shape, the interior can be customized with EPE pearl cotton, EPS foam, or wooden card slots for a "tailor-made" wrapping. Heavy equipment often uses a double-secured method of steel strapping and wooden wedges to completely eliminate the risk of displacement during transport. For high-value precision instruments, shock-absorbing brackets or air column bags can be integrated to absorb high-frequency vibration energy and prevent micron-level damage.

5. Standardization and Traceability: Ensuring Global Logistics Compatibility

Fumigation-free wooden boxes are clearly marked with IPPC fumigation-free markings, load-bearing capacity, and lifting direction information, facilitating rapid identification and operation at global logistics nodes. Some manufacturers also provide structural strength calculations and drop test reports, giving customers peace of mind.

The high strength of fumigation-free wooden boxes does not come from the advantages of a single material, but from the integrated system of materials, structure, connections, and lining systems. It redefines the "wooden crate" with an engineering mindset—no longer a crude, temporary package, but a mobile fortress tailored for heavy equipment. In the era of global trade that emphasizes both efficiency and compliance, this intelligent packaging solution, which is both fumigation-free and can withstand long journeys, is becoming an indispensable "invisible guardian" for high-end manufacturing going global.