How can fumigation-free wooden pallets achieve efficient forklift operations in automated warehousing?

Release Time : 2025-09-04

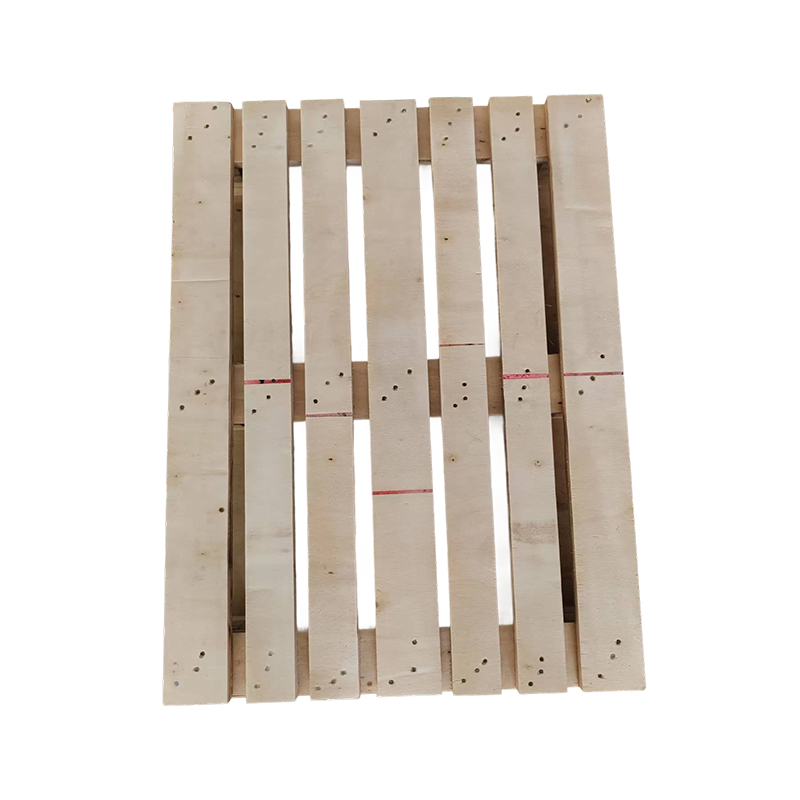

In modern intelligent warehousing and logistics systems, automated forklifts (such as automated guided vehicles (AGVs), guided vehicle (RGVs), and stacker trucks) are gradually replacing traditional manual operations and becoming the core force in cargo handling. Pallets, as cargo-carrying units, require standardization, stability, and compatibility that directly impact the efficiency and reliability of automated systems. Among various pallet types, fumigation-free wooden pallets, with their sturdy structure, precise dimensions, and smooth surface, have become an ideal loading platform in automated warehousing systems.

1. Standardized Dimensions: Ensure Accurate Forklift Positioning and Quick Docking

Automated forklifts rely on laser navigation, vision recognition, or magnetic stripe positioning systems for path planning and cargo handling. Their picking and unloading operations are highly dependent on the geometric consistency of the pallet. Fumigation-free wooden pallets are constructed from multiple layers of plywood or particleboard, pressed under high temperature and pressure, and their production strictly adheres to international standards. This high-precision dimensional consistency enables automated forklifts to precisely insert their forks into the pallet's fork opening (in two or four directions), enabling "one-time" pick-and-place operations. This avoids fork jamming, misalignment, or failures caused by pallet deformation or dimensional deviation, significantly improving handling cycle time and system stability.

2. Sturdy Structure to Meet High-Load and Dynamic Handling Requirements

Automated warehousing often involves multi-layer stacking, high-speed handling, and frequent lifting and lowering, placing extremely high demands on pallets' load-bearing capacity and impact resistance. Fumigation-free wooden pallets utilize a multi-layer, cross-bonded board structure for high overall strength, making them resistant to cracking, warping, or breaking. They can withstand static loads of 3-5 tons and dynamic loads of 1-1.5 tons, offering excellent stacking capacity and the ability to safely carry heavy industrial equipment, metal products, or densely packaged fast-moving consumer goods. During high-speed operation of automated forklifts, pallets are subject to dynamic stresses caused by acceleration, vibration, and sudden stops. The rigid structure of fumigation-free pallets effectively distributes these forces, preventing cargo from tipping or collapsing, ensuring safe and efficient handling.

3. Smooth, Burr-Free Surface Protects Equipment and Goods

Traditional solid wood pallets often have problems such as splinters, exposed nail heads, and wide gaps between slats. These can not only damage packaging but can also scratch the tires or sensors of automated forklifts. Fumigation-free wooden pallets, on the other hand, offer a smooth, burr-free, and protruding surface, with tight seams and high overall flatness. This feature not only protects the outer packaging of high-value goods such as precision electronic equipment and automotive parts, but also prevents physical interference with the automated forklift's underbody sensors, laser scanners, or navigation systems, ensuring long-term stable operation and minimizing downtime.

4. Four-Way Access Design Enhances Operational Flexibility

Most fumigation-free wooden pallets feature a four-way access structure, allowing forklifts to freely enter and exit from all four directions without directional restrictions. This design significantly enhances the dispatching flexibility of automated systems. In densely packed racking arrangements, forklifts can access pallets from any direction without turning or precisely aligning, shortening access paths and optimizing storage space utilization. Furthermore, standardized fork entry heights and opening dimensions ensure compatibility with automated forklifts of varying makes and models, enhancing the system's versatility and scalability.

5. Barcode and RFID Compatibility, Supporting Intelligent Identification

Modern fumigation-free wooden pallets can be integrated with barcode labels or RFID chips to record cargo information, batches, destinations, and other data. Their flat surface provides an ideal carrier for attaching and reading electronic tags. Automated forklifts use scanning systems to identify pallet contents in real time, enabling automated sorting, route planning, and inventory management, creating a closed-loop intelligent logistics system where "goods follow orders."

6. Environmental Compliance Streamlines Cross-Border Warehousing

Fumigation-free wooden pallets comply with the International Plant Quarantine Standard (ISPM-15). They require no fumigation or heat treatment and are globally usable with the IPPC label. In multinational automated warehousing centers or cross-border logistics hubs, this feature prevents cargo from being held up due to quarantine delays, ensuring the continuous and efficient operation of the automated system.

The fumigation-free wooden pallet is not only a cargo carrier but also the "key interface" connecting automated forklifts and intelligent warehousing systems. Through standardized dimensions, a robust structure, a flat surface, four-way access, and intelligent identification compatibility, it provides a stable, efficient, and safe foundation for automated handling.

1. Standardized Dimensions: Ensure Accurate Forklift Positioning and Quick Docking

Automated forklifts rely on laser navigation, vision recognition, or magnetic stripe positioning systems for path planning and cargo handling. Their picking and unloading operations are highly dependent on the geometric consistency of the pallet. Fumigation-free wooden pallets are constructed from multiple layers of plywood or particleboard, pressed under high temperature and pressure, and their production strictly adheres to international standards. This high-precision dimensional consistency enables automated forklifts to precisely insert their forks into the pallet's fork opening (in two or four directions), enabling "one-time" pick-and-place operations. This avoids fork jamming, misalignment, or failures caused by pallet deformation or dimensional deviation, significantly improving handling cycle time and system stability.

2. Sturdy Structure to Meet High-Load and Dynamic Handling Requirements

Automated warehousing often involves multi-layer stacking, high-speed handling, and frequent lifting and lowering, placing extremely high demands on pallets' load-bearing capacity and impact resistance. Fumigation-free wooden pallets utilize a multi-layer, cross-bonded board structure for high overall strength, making them resistant to cracking, warping, or breaking. They can withstand static loads of 3-5 tons and dynamic loads of 1-1.5 tons, offering excellent stacking capacity and the ability to safely carry heavy industrial equipment, metal products, or densely packaged fast-moving consumer goods. During high-speed operation of automated forklifts, pallets are subject to dynamic stresses caused by acceleration, vibration, and sudden stops. The rigid structure of fumigation-free pallets effectively distributes these forces, preventing cargo from tipping or collapsing, ensuring safe and efficient handling.

3. Smooth, Burr-Free Surface Protects Equipment and Goods

Traditional solid wood pallets often have problems such as splinters, exposed nail heads, and wide gaps between slats. These can not only damage packaging but can also scratch the tires or sensors of automated forklifts. Fumigation-free wooden pallets, on the other hand, offer a smooth, burr-free, and protruding surface, with tight seams and high overall flatness. This feature not only protects the outer packaging of high-value goods such as precision electronic equipment and automotive parts, but also prevents physical interference with the automated forklift's underbody sensors, laser scanners, or navigation systems, ensuring long-term stable operation and minimizing downtime.

4. Four-Way Access Design Enhances Operational Flexibility

Most fumigation-free wooden pallets feature a four-way access structure, allowing forklifts to freely enter and exit from all four directions without directional restrictions. This design significantly enhances the dispatching flexibility of automated systems. In densely packed racking arrangements, forklifts can access pallets from any direction without turning or precisely aligning, shortening access paths and optimizing storage space utilization. Furthermore, standardized fork entry heights and opening dimensions ensure compatibility with automated forklifts of varying makes and models, enhancing the system's versatility and scalability.

5. Barcode and RFID Compatibility, Supporting Intelligent Identification

Modern fumigation-free wooden pallets can be integrated with barcode labels or RFID chips to record cargo information, batches, destinations, and other data. Their flat surface provides an ideal carrier for attaching and reading electronic tags. Automated forklifts use scanning systems to identify pallet contents in real time, enabling automated sorting, route planning, and inventory management, creating a closed-loop intelligent logistics system where "goods follow orders."

6. Environmental Compliance Streamlines Cross-Border Warehousing

Fumigation-free wooden pallets comply with the International Plant Quarantine Standard (ISPM-15). They require no fumigation or heat treatment and are globally usable with the IPPC label. In multinational automated warehousing centers or cross-border logistics hubs, this feature prevents cargo from being held up due to quarantine delays, ensuring the continuous and efficient operation of the automated system.

The fumigation-free wooden pallet is not only a cargo carrier but also the "key interface" connecting automated forklifts and intelligent warehousing systems. Through standardized dimensions, a robust structure, a flat surface, four-way access, and intelligent identification compatibility, it provides a stable, efficient, and safe foundation for automated handling.