How can using fumigation-free wooden pallets reduce cargo damage?

Release Time : 2025-09-18

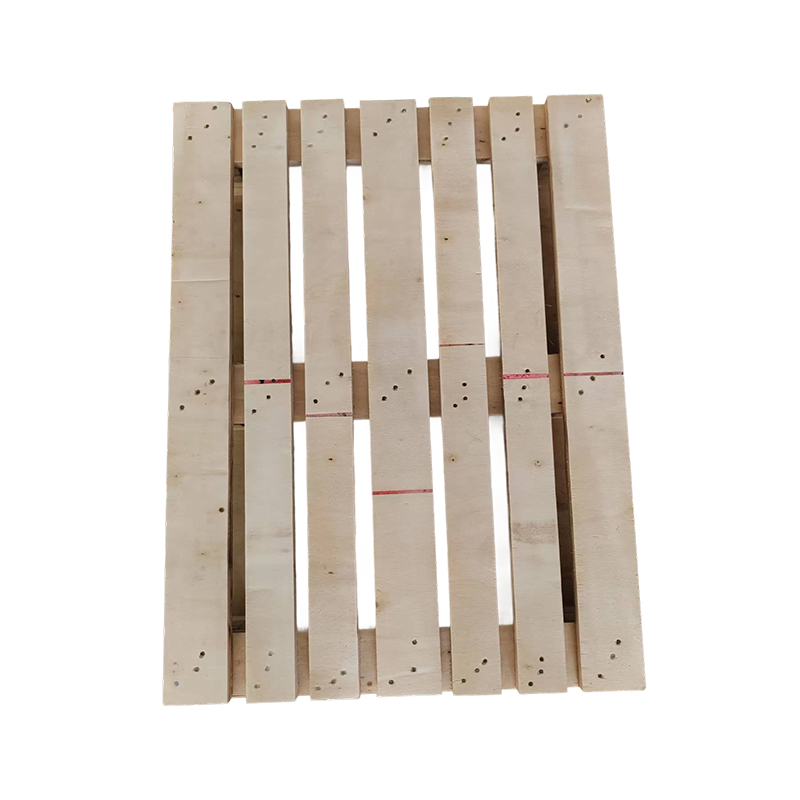

In modern logistics, transportation, and warehousing, cargo integrity is a key indicator of supply chain efficiency. Even minor damage at any stage can lead to customer complaints, product returns, and even damage to brand reputation. Therefore, choosing the right carrier is crucial. Fumigation-free wooden pallets, as a stable, environmentally friendly transport carrier that meets international standards, are increasingly being adopted by businesses.

1. Sturdy Structure and Strong Load-Carrying Capacity

Fumigation-free wooden pallets are typically made from multiple layers of plywood or high-strength particleboard through a hot-pressing process. Their scientifically designed structure offers excellent compressive and bending resistance. Compared to traditional solid wood pallets, which may have natural defects such as knots and cracks, fumigation-free wooden pallets feature a uniform material, are insect-free, and remain crack-free, resulting in greater overall strength. This stability effectively distributes the weight of cargo, preventing tilting or collapse caused by pallet deformation or breakage, significantly reducing the risk of damage.

2. Smooth Surface, Protecting the Cargo Bottom

The surface of a fumigation-free wooden pallet is smooth and flat, free of burrs and exposed nail heads. This is particularly important during handling. For goods with soft bottom materials or delicate packaging, direct contact with rough or uneven pallet surfaces can easily cause scratches, dents, or even cracks in the packaging. The flat surface of a fumigation-free wooden pallet provides uniform support, reduces localized pressure concentration, and maximizes the appearance and structural integrity of the goods.

3. Moisture- and mildew-resistant, enhancing storage and transportation safety

Traditional solid wood pallets, if not properly treated, easily absorb moisture from the air, causing mold, deformation, and even bacterial growth. This problem is particularly prominent during sea transportation or in humid environments. Fumigation-free wooden pallets, on the other hand, undergo high-temperature and high-pressure treatment during production to maintain a reasonable moisture content and provide excellent moisture resistance. This not only extends the pallet's lifespan but also prevents moisture-induced softening, which can reduce its load-bearing capacity and prevent damage to goods due to support failure.

4. Standardized Dimensions, Compatible with Automated Equipment

Modern warehousing and logistics increasingly utilize automated equipment, such as forklifts, stackers, and automated sorting systems. Fumigation-free wooden pallets adhere to international standard dimensions. Their precise dimensions and clean edges allow for seamless integration with various handling equipment. This standardized design reduces the risk of collision, misalignment, and slippage during loading and unloading, improving operational stability and efficiency, and indirectly reducing damage to goods caused by improper handling or equipment mismatch.

5. No Fumigation Required, Avoiding Chemical Residue Contamination

Traditional solid wood pallets require fumigation with chemicals such as methyl bromide before export to meet international plant quarantine standards. However, this fumigation process is not only time-consuming and labor-intensive, but can also leave harmful chemical residues in the wood, posing a potential contamination risk to sensitive goods such as food, pharmaceuticals, and cosmetics. Fumigation-free wooden pallets, made of synthetic wood, already meet export quarantine requirements and require no chemical treatment. This fundamentally eliminates cargo contamination or packaging corrosion caused by fumigation residue, ensuring cargo safety and quality.

6. Customizable Design to Meet Special Cargo Needs

Fumigation-free wooden pallets can be customized to meet specific cargo needs and industry requirements. For example, anti-slip mats and corner protection strips can be added for fragile items; the pallet frame can be reinforced for heavy machinery; and anti-static pallets can be manufactured for electronic components requiring static protection. This flexibility allows the pallet to better match the specific characteristics of the cargo, providing targeted protection and further reducing damage caused by vibration, friction, and impact during transportation.

In summary, the fumigation-free wooden pallet, with its multiple advantages including stable structure, smooth surface, moisture-resistant and durable design, standard specifications, absence of chemical residues, and customization, has significantly improved the safety and reliability of cargo transportation in practical applications. For businesses, choosing fumigation-free wooden pallets is not only a wise move to comply with environmental protection and international logistics trends, but also an effective strategy to reduce cargo damage rates, improve customer satisfaction, and optimize supply chain management.

1. Sturdy Structure and Strong Load-Carrying Capacity

Fumigation-free wooden pallets are typically made from multiple layers of plywood or high-strength particleboard through a hot-pressing process. Their scientifically designed structure offers excellent compressive and bending resistance. Compared to traditional solid wood pallets, which may have natural defects such as knots and cracks, fumigation-free wooden pallets feature a uniform material, are insect-free, and remain crack-free, resulting in greater overall strength. This stability effectively distributes the weight of cargo, preventing tilting or collapse caused by pallet deformation or breakage, significantly reducing the risk of damage.

2. Smooth Surface, Protecting the Cargo Bottom

The surface of a fumigation-free wooden pallet is smooth and flat, free of burrs and exposed nail heads. This is particularly important during handling. For goods with soft bottom materials or delicate packaging, direct contact with rough or uneven pallet surfaces can easily cause scratches, dents, or even cracks in the packaging. The flat surface of a fumigation-free wooden pallet provides uniform support, reduces localized pressure concentration, and maximizes the appearance and structural integrity of the goods.

3. Moisture- and mildew-resistant, enhancing storage and transportation safety

Traditional solid wood pallets, if not properly treated, easily absorb moisture from the air, causing mold, deformation, and even bacterial growth. This problem is particularly prominent during sea transportation or in humid environments. Fumigation-free wooden pallets, on the other hand, undergo high-temperature and high-pressure treatment during production to maintain a reasonable moisture content and provide excellent moisture resistance. This not only extends the pallet's lifespan but also prevents moisture-induced softening, which can reduce its load-bearing capacity and prevent damage to goods due to support failure.

4. Standardized Dimensions, Compatible with Automated Equipment

Modern warehousing and logistics increasingly utilize automated equipment, such as forklifts, stackers, and automated sorting systems. Fumigation-free wooden pallets adhere to international standard dimensions. Their precise dimensions and clean edges allow for seamless integration with various handling equipment. This standardized design reduces the risk of collision, misalignment, and slippage during loading and unloading, improving operational stability and efficiency, and indirectly reducing damage to goods caused by improper handling or equipment mismatch.

5. No Fumigation Required, Avoiding Chemical Residue Contamination

Traditional solid wood pallets require fumigation with chemicals such as methyl bromide before export to meet international plant quarantine standards. However, this fumigation process is not only time-consuming and labor-intensive, but can also leave harmful chemical residues in the wood, posing a potential contamination risk to sensitive goods such as food, pharmaceuticals, and cosmetics. Fumigation-free wooden pallets, made of synthetic wood, already meet export quarantine requirements and require no chemical treatment. This fundamentally eliminates cargo contamination or packaging corrosion caused by fumigation residue, ensuring cargo safety and quality.

6. Customizable Design to Meet Special Cargo Needs

Fumigation-free wooden pallets can be customized to meet specific cargo needs and industry requirements. For example, anti-slip mats and corner protection strips can be added for fragile items; the pallet frame can be reinforced for heavy machinery; and anti-static pallets can be manufactured for electronic components requiring static protection. This flexibility allows the pallet to better match the specific characteristics of the cargo, providing targeted protection and further reducing damage caused by vibration, friction, and impact during transportation.

In summary, the fumigation-free wooden pallet, with its multiple advantages including stable structure, smooth surface, moisture-resistant and durable design, standard specifications, absence of chemical residues, and customization, has significantly improved the safety and reliability of cargo transportation in practical applications. For businesses, choosing fumigation-free wooden pallets is not only a wise move to comply with environmental protection and international logistics trends, but also an effective strategy to reduce cargo damage rates, improve customer satisfaction, and optimize supply chain management.