How do fumigation-free wooden boxes meet the challenges of long-distance ocean shipping?

Release Time : 2025-10-03

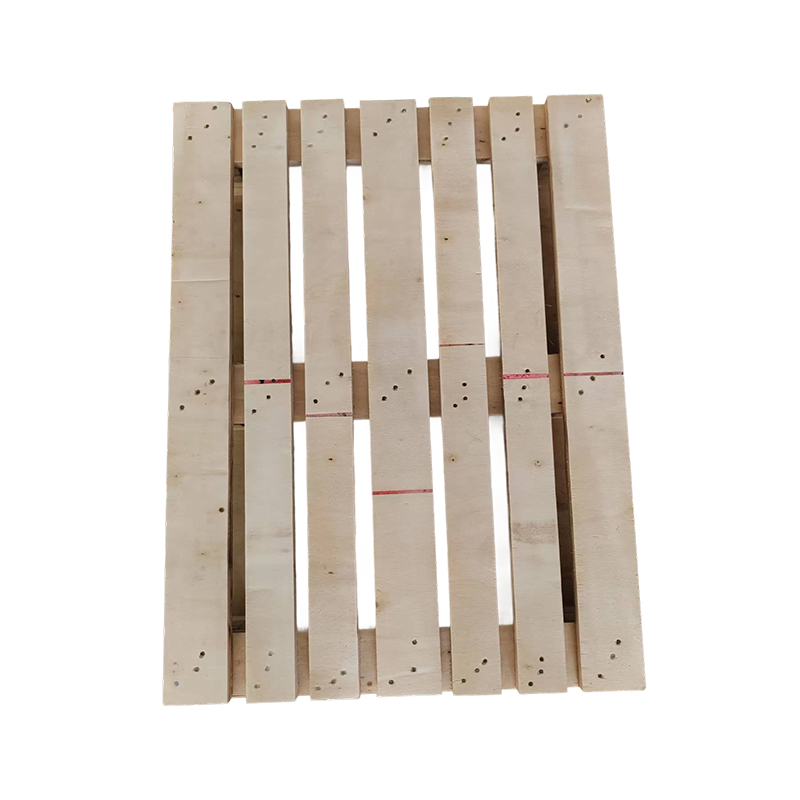

With increasingly globalized trade, long-distance ocean shipping, as the primary mode of transporting bulk goods, carries countless industrial equipment, mechanical parts, electronic products, and heavy commodities across borders. However, the complex and dynamic maritime environment—long periods of turbulence, high humidity and salinity, stacking pressure, temperature fluctuations, and biological attack—places extremely high demands on the strength and durability of packaging boxes. At the same time, countries are increasingly stringent in their quarantine standards for wood packaging materials. Traditional solid wood boxes require cumbersome fumigation treatments before export, which is not only costly but also carries the risk of delays. Against this backdrop, fumigation-free wooden boxes, with their unique material advantages and structural design, are an ideal packaging solution for meeting the challenges of long-distance ocean shipping.

1. Comply with international standards and ensure smooth customs clearance

The primary challenge of long-distance ocean shipping is regulatory compliance. To prevent the spread of pests through wood packaging, many countries mandate that all solid wood packaging undergo heat treatment or fumigation. Fumigation-free wooden boxes are made from man-made boards such as plywood, particleboard, and medium-density fiberboard. The high-temperature and high-pressure processes used during their production effectively kill insect eggs and pathogens. This not only simplifies the export process and avoids missed shipments due to fumigation delays, but also ensures smooth customs clearance at the destination port, reducing trade friction and additional costs.

2. High-strength structure to withstand physical impact during transportation

During sea transportation, containers often experience prolonged sea turbulence, loading and unloading shocks, and multiple layers of stacking. Fumigation-free wooden boxes are typically constructed from multi-layer plywood or high-strength composite wood. These boards are uniform, knot-free, and crack-free, offering excellent resistance to compression, bending, and impact. The box design often utilizes mortise and tenon joints, metal corner reinforcements, or full-surround steel strapping to ensure a stable overall structure capable of withstanding tons of stacking pressure without deformation or collapse. Even in harsh sea conditions and severe shaking, they effectively protect the cargo inside from damage from crushing, collision, and vibration.

3. Moisture- and mildew-resistant, suitable for high-humidity maritime environments

Ocean shipping often traverses tropical and subtropical waters, where "sweat" easily forms inside containers. Diurnal temperature swings cause condensation and extremely high humidity. Traditional solid wooden boxes are prone to moisture absorption, swelling, mold, and rot, compromising their structural strength. Fumigation-free wooden boxes, on the other hand, are made from artificial boards treated for moisture resistance during production. Some products are also bonded with waterproof adhesive and can be coated or sprayed with a moisture-proof coating, significantly enhancing their moisture and mildew resistance. Even in long-term storage in high-humidity environments, they maintain structural stability, preventing softening and mildew, ensuring the dryness and safety of cargo.

4. Lightweight design reduces transportation costs

Compared to traditional solid wood boxes, fumigation-free wooden boxes are lighter while maintaining strength. This not only facilitates handling and loading and unloading, but also effectively reduces overall logistics costs, especially in weight-based shipping. The lightweight design also means greater loading efficiency, helping businesses optimize container space utilization and improve transportation efficiency.

5. Environmentally friendly and recyclable, in line with green trade trends

Fumigation-free wooden boxes are mostly made from renewable wood resources or recycled materials. The production process is chemical-free and can be recycled or safely disposed of after use, meeting international environmental standards. An increasing number of multinational companies are prioritizing green packaging as a key component of supply chain management. The environmentally friendly nature of fumigation-free wooden boxes makes them more competitive in the international market.

In summary, fumigation-free wooden boxes, with their multiple advantages—including compliance and inspection exemption, high-strength construction, moisture-resistant durability, lightweight design, and environmental friendliness—successfully address the multiple challenges of long-distance ocean shipping, including customs clearance, physical, environmental, and cost challenges. More than just a packaging container, they are a crucial tool for ensuring cargo safety, improving logistics efficiency, and facilitating the smooth flow of international trade.

1. Comply with international standards and ensure smooth customs clearance

The primary challenge of long-distance ocean shipping is regulatory compliance. To prevent the spread of pests through wood packaging, many countries mandate that all solid wood packaging undergo heat treatment or fumigation. Fumigation-free wooden boxes are made from man-made boards such as plywood, particleboard, and medium-density fiberboard. The high-temperature and high-pressure processes used during their production effectively kill insect eggs and pathogens. This not only simplifies the export process and avoids missed shipments due to fumigation delays, but also ensures smooth customs clearance at the destination port, reducing trade friction and additional costs.

2. High-strength structure to withstand physical impact during transportation

During sea transportation, containers often experience prolonged sea turbulence, loading and unloading shocks, and multiple layers of stacking. Fumigation-free wooden boxes are typically constructed from multi-layer plywood or high-strength composite wood. These boards are uniform, knot-free, and crack-free, offering excellent resistance to compression, bending, and impact. The box design often utilizes mortise and tenon joints, metal corner reinforcements, or full-surround steel strapping to ensure a stable overall structure capable of withstanding tons of stacking pressure without deformation or collapse. Even in harsh sea conditions and severe shaking, they effectively protect the cargo inside from damage from crushing, collision, and vibration.

3. Moisture- and mildew-resistant, suitable for high-humidity maritime environments

Ocean shipping often traverses tropical and subtropical waters, where "sweat" easily forms inside containers. Diurnal temperature swings cause condensation and extremely high humidity. Traditional solid wooden boxes are prone to moisture absorption, swelling, mold, and rot, compromising their structural strength. Fumigation-free wooden boxes, on the other hand, are made from artificial boards treated for moisture resistance during production. Some products are also bonded with waterproof adhesive and can be coated or sprayed with a moisture-proof coating, significantly enhancing their moisture and mildew resistance. Even in long-term storage in high-humidity environments, they maintain structural stability, preventing softening and mildew, ensuring the dryness and safety of cargo.

4. Lightweight design reduces transportation costs

Compared to traditional solid wood boxes, fumigation-free wooden boxes are lighter while maintaining strength. This not only facilitates handling and loading and unloading, but also effectively reduces overall logistics costs, especially in weight-based shipping. The lightweight design also means greater loading efficiency, helping businesses optimize container space utilization and improve transportation efficiency.

5. Environmentally friendly and recyclable, in line with green trade trends

Fumigation-free wooden boxes are mostly made from renewable wood resources or recycled materials. The production process is chemical-free and can be recycled or safely disposed of after use, meeting international environmental standards. An increasing number of multinational companies are prioritizing green packaging as a key component of supply chain management. The environmentally friendly nature of fumigation-free wooden boxes makes them more competitive in the international market.

In summary, fumigation-free wooden boxes, with their multiple advantages—including compliance and inspection exemption, high-strength construction, moisture-resistant durability, lightweight design, and environmental friendliness—successfully address the multiple challenges of long-distance ocean shipping, including customs clearance, physical, environmental, and cost challenges. More than just a packaging container, they are a crucial tool for ensuring cargo safety, improving logistics efficiency, and facilitating the smooth flow of international trade.