Why can fumigation-free wooden boxes be used directly for international transport without fumigation?

Release Time : 2025-10-16

With the increasing frequency of international trade, the use of wood packaging materials faces stringent quarantine requirements. To prevent the spread of exotic pests (such as pine wood nematodes and bark beetles) through wooden pallets and boxes, many countries require that solid wood packaging undergo high-temperature fumigation or heat treatment and be affixed with the IPPC mark before entry. This process not only increases time and costs but can also cause delays due to improper handling. The emergence of fumigation-free wooden boxes aims to overcome this bottleneck, providing a compliant packaging solution that eliminates the need for fumigation and allows for direct customs clearance.

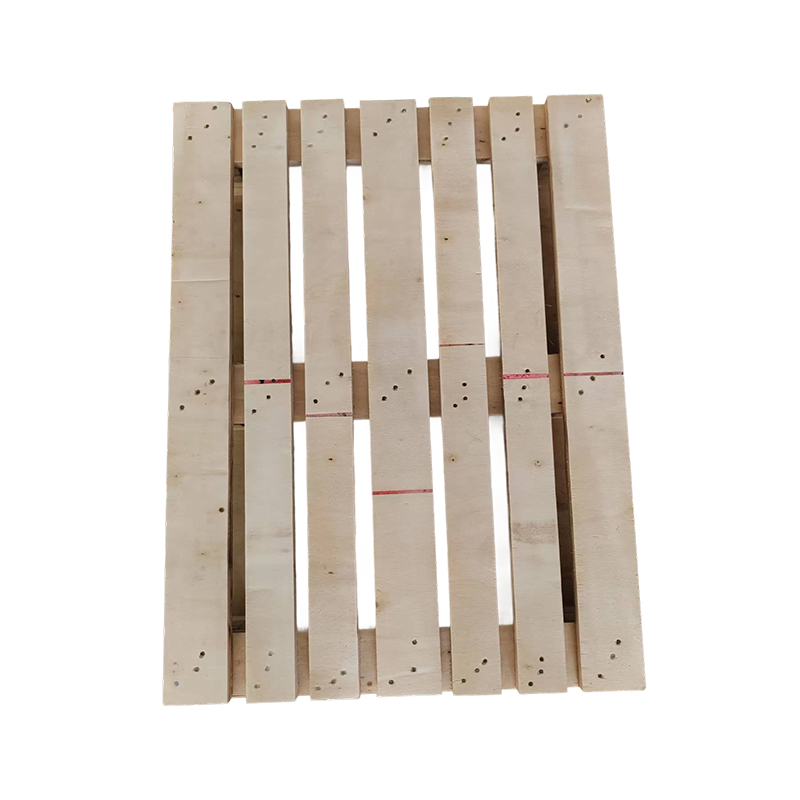

The core of fumigation-free wooden boxes lies in their material composition. They are not made from natural logs, but rather from synthetic boards such as multi-layer plywood, oriented strand board (OSB), and medium-density fiberboard (MDF). These boards undergo high-temperature and high-pressure treatment during the production process, completely breaking up and re-bonding the wood fibers. The internal temperatures are sufficient to kill all possible insect eggs, fungi, and pathogens. This manufacturing process inherently meets the International Plant Protection Convention (IPPC) heat treatment standards for wood packaging materials. Therefore, wooden boxes made from this material are considered "harmless carriers" and no longer require additional fumigation or chemical treatment. They can be affixed with the IPPC label upon leaving the factory, making them eligible for direct export.

Beyond regulatory compliance, fumigation-free wooden boxes also offer excellent performance. Their compact structure and uniform material resist cracking, deformation, and splintering, and they can withstand the weight of heavy equipment and the crushing and vibrations of transportation. The boxes can be designed to be fully enclosed, removable, or foldable, making them easy to load, secure, and recycle. Their smooth surface is ideal for printing corporate logos or logistics information, enhancing the packaging's professionalism and brand image.

Environmentally, fumigation-free wooden boxes are often made from fast-growing wood or recycled wood fiber, reducing reliance on natural forests and aligning with sustainable development. Their reusability and recyclability also reduce the environmental impact of packaging waste.

Furthermore, fumigation-free wooden boxes significantly improve logistics efficiency. Businesses no longer have to wait for fumigation cycles and can arrange packaging and shipment immediately, shortening delivery times. This advantage is particularly significant for urgent orders or bulk exports. Furthermore, it avoids odor residue or chemical contamination that may occur during the fumigation process, making it particularly suitable for industries with high cleanliness requirements, such as food machinery, medical equipment, and electronics.

Ultimately, the value of the fumigation-free wooden box lies not only in its fumigation-free nature but also in its integration of regulatory compliance, efficiency, safety, and environmental protection. It replaces cumbersome quarantine procedures with material science and eliminates trade barriers with industrialized production, making it an indispensable smart packaging solution in modern international logistics. Behind the smooth customs clearance of each piece of equipment lies the silent support these wooden boxes provide for the efficient operation of the global supply chain.

The core of fumigation-free wooden boxes lies in their material composition. They are not made from natural logs, but rather from synthetic boards such as multi-layer plywood, oriented strand board (OSB), and medium-density fiberboard (MDF). These boards undergo high-temperature and high-pressure treatment during the production process, completely breaking up and re-bonding the wood fibers. The internal temperatures are sufficient to kill all possible insect eggs, fungi, and pathogens. This manufacturing process inherently meets the International Plant Protection Convention (IPPC) heat treatment standards for wood packaging materials. Therefore, wooden boxes made from this material are considered "harmless carriers" and no longer require additional fumigation or chemical treatment. They can be affixed with the IPPC label upon leaving the factory, making them eligible for direct export.

Beyond regulatory compliance, fumigation-free wooden boxes also offer excellent performance. Their compact structure and uniform material resist cracking, deformation, and splintering, and they can withstand the weight of heavy equipment and the crushing and vibrations of transportation. The boxes can be designed to be fully enclosed, removable, or foldable, making them easy to load, secure, and recycle. Their smooth surface is ideal for printing corporate logos or logistics information, enhancing the packaging's professionalism and brand image.

Environmentally, fumigation-free wooden boxes are often made from fast-growing wood or recycled wood fiber, reducing reliance on natural forests and aligning with sustainable development. Their reusability and recyclability also reduce the environmental impact of packaging waste.

Furthermore, fumigation-free wooden boxes significantly improve logistics efficiency. Businesses no longer have to wait for fumigation cycles and can arrange packaging and shipment immediately, shortening delivery times. This advantage is particularly significant for urgent orders or bulk exports. Furthermore, it avoids odor residue or chemical contamination that may occur during the fumigation process, making it particularly suitable for industries with high cleanliness requirements, such as food machinery, medical equipment, and electronics.

Ultimately, the value of the fumigation-free wooden box lies not only in its fumigation-free nature but also in its integration of regulatory compliance, efficiency, safety, and environmental protection. It replaces cumbersome quarantine procedures with material science and eliminates trade barriers with industrialized production, making it an indispensable smart packaging solution in modern international logistics. Behind the smooth customs clearance of each piece of equipment lies the silent support these wooden boxes provide for the efficient operation of the global supply chain.