How does the structural design of a fumigation-free wooden pallet ensure the stability of cargo transportation?

Release Time : 2025-10-30

As a crucial cargo-carrying unit in modern logistics, the fumigation-free wooden pallet's structural design, through scientific planning and process optimization, provides comprehensive assurance for the stability of cargo transportation. The fact that this pallet can be exported directly without fumigation treatment makes it an efficient and environmentally friendly logistics tool in international trade, while its stability design permeates multiple levels, including material selection, structural layout, and functional integration.

From a material perspective, fumigation-free wooden pallets primarily utilize plywood, composite boards, or plant fiber molded materials. These materials form a stable structure through multi-layer bonding or molding processes. Plywood is made by hot-pressing multiple layers of veneers in a crisscross pattern, with each layer having perpendicular grain, effectively dispersing pressure and resisting deformation. Composite boards combine polymer materials with wood fibers, enhancing impact resistance and weather resistance. Plant fiber molded pallets use wood shavings, straw, and other raw materials, with integral molding ensuring a dense structure. These materials share the characteristics of high strength, light weight, and resistance to cracking, laying the foundation for transportation stability from the outset.

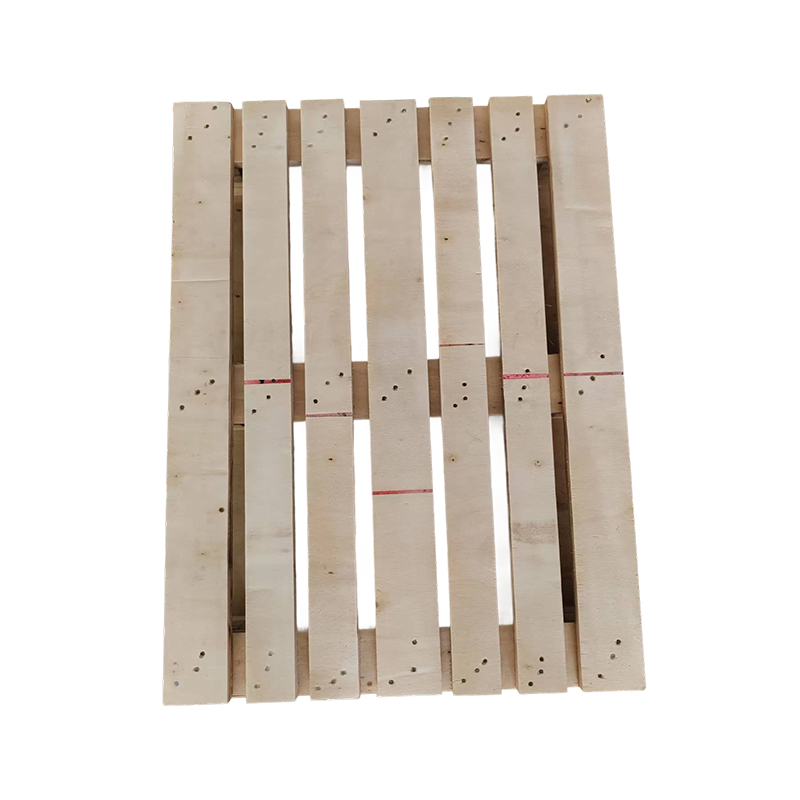

In terms of structural layout, the fumigation-free wooden pallet achieves functional zoning through modular design. The panels are typically made of a single piece of plywood or spliced panels, with a smooth, flat surface to reduce the risk of goods slipping. Edges are sealed to prevent moisture penetration and expansion. The legs are designed in nine-leg, three-leg, or grid patterns depending on load-bearing requirements: the lightweight nine-leg design is suitable for light goods; the three-leg design with three longitudinal beams enhances forklift adaptability; and the grid structure distributes weight evenly to meet the needs of heavy goods. Bottom reinforcing ribs further distribute pressure, preventing excessive localized stress and deformation.

Dynamic stability is the core of the fumigation-free wooden pallet design. During transportation, the pallet must withstand the weight of the goods, vibration, impact, and changes in ambient temperature and humidity. Therefore, the design adopts a principle of balanced longitudinal and transverse forces. For example, the grid structure of the grid pallet distributes pressure to multiple support points, while the nine-leg pallet ensures stability when a forklift inserts from four directions through a rational distribution of legs. Furthermore, the surface anti-slip treatment employs a special coating or texture design to increase friction between goods and the pallet, preventing goods from shifting during transport.

For different transport scenarios, fumigation-free wooden pallets offer customized solutions. For moisture-sensitive goods, drainage holes or a waterproof coating can be added to the bottom of the pallet; for precision instruments, soft cushioning materials can be embedded in the panel to absorb vibration; for cold chain transport, materials must be selected with low-temperature crack resistance. This flexibility allows the pallet to adapt to diverse needs from ambient temperature storage to extreme environment transport, ensuring that goods remain stable at all times.

Optimized design of the contact surface with goods is equally crucial. The panel thickness of fumigation-free wooden pallets is typically controlled between 12-18 mm, ensuring strength while avoiding excessive thickness that would raise the center of gravity. Rounded edges prevent scratching the packaging and reduce stress concentration caused by collisions during transport. Some high-end products also embed memory foam wrist rests or anti-slip pads in the panel to further enhance the stability of the goods.

Long-term stability is achieved through meticulous craftsmanship. Molded pallets utilize a one-piece molding technology, eliminating the risk of cracking caused by seams; plywood pallets undergo high-temperature and high-pressure treatment to ensure interlayer bonding strength; reinforcing ribs or metal inserts are used at the connection between the legs and the panel to prevent loosening caused by repeated loading and unloading. These process details extend the pallet's lifespan and reduce transportation accidents caused by structural damage.

The structural design of fumigation-free wooden pallets, through a deep integration of materials science, mechanical principles, and manufacturing technology, constructs a complete system to ensure transportation stability. From static load-bearing capacity to dynamic impact, from environmental adaptability to durability, every design element aims to maximize cargo safety. This systematic design not only improves logistics efficiency but also promotes international trade towards a more efficient and environmentally friendly direction.