How can we ensure consistent quality during the production of fumigation-free wooden pallets?

Release Time : 2025-11-13

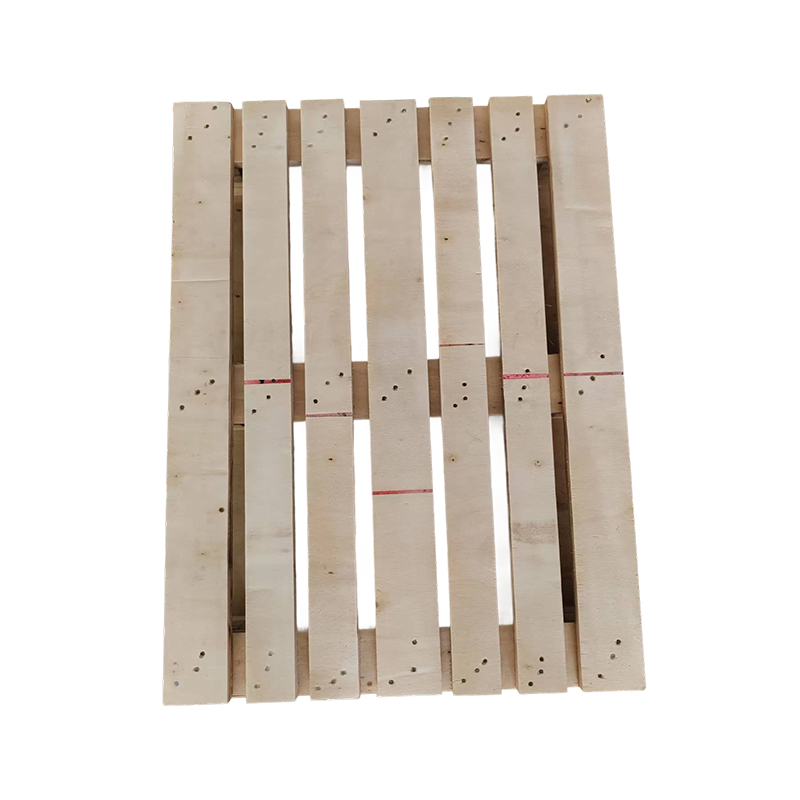

The quality and stability of fumigation-free wooden pallets directly impact the safety and efficiency of logistics and transportation. Their production process requires coordinated control across multiple stages, from raw material selection and process control to structural optimization, quality testing, and environmental management, to ensure that each pallet meets international standards and practical application requirements.

Raw material selection is the foundation of quality stability. Fumigation-free wooden pallets primarily use engineered wood products such as plywood, composite boards, or oriented strand board (OSB). These materials are laminated using high-temperature, high-pressure processes to bond wood chips or fibers, avoiding problems like insect infestation and decay inherent in natural wood, and enhancing overall stability through a uniform material structure. Reputable suppliers rigorously test the moisture content, bonding strength, and formaldehyde emissions of the boards to ensure compliance with environmental protection and durability requirements, preventing deformation or cracking caused by material defects from the outset.

Refined processing techniques are a core element. Production requires precise cutting, drilling, and splicing of the boards using specialized equipment. For example, CNC machine tools are used to ensure the consistency of dimensions for all pallet components, avoiding structural strength compromised by human error. Meanwhile, high-strength adhesives or metal connectors must be used at the joints, and a pressure curing process must be applied to ensure a firm connection and prevent loosening during long-term use. Some companies also introduce thermoforming technology, using high temperature and high pressure to further eliminate internal stress in the boards and improve bending resistance.

The scientific nature of the structural design directly affects load-bearing capacity and stability. Fumigation-free wooden pallets typically use a frame structure of "top and bottom panels + support beams," where the layout of the support beams needs to be optimized according to the pallet size and load-bearing requirements. For example, heavy-duty pallets increase the number of support beams or use thicker boards to distribute the pressure of the goods; while light-duty pallets reduce costs by using less material while maintaining sufficient strength. Furthermore, the chamfering of the pallet edges and the anti-slip texture design on the surface can reduce collision damage during transportation and prevent goods from sliding, improving safety during use.

A comprehensive quality inspection system is crucial. Multiple inspection steps must be set up during the production process, including raw material inspection upon warehousing, semi-finished product dimensional verification, finished product load-bearing testing, and screening for appearance defects. For example, static and dynamic load tests simulating real-world usage scenarios verify the pallet's compressive strength during stacking and handling; moisture content meters ensure the board's humidity meets standards, preventing expansion or contraction due to environmental humidity changes. Some companies also introduce third-party certifications, such as ISO 9001 quality management system certification or the IPPC mark (International Plant Protection Convention certification), to prove that their products comply with international standards.

Environmental control is equally crucial. The temperature and humidity in the production workshop must be kept stable to prevent board deformation due to environmental fluctuations. For example, high temperatures may cause adhesives to cure too quickly, affecting splicing strength; while high humidity may cause the boards to absorb moisture and expand, compromising structural stability. Therefore, companies typically equip themselves with temperature and humidity control equipment and regularly monitor production environment data to ensure that every step is completed under controllable conditions.

Standardized supply chain management is a long-term guarantee. From raw material procurement to finished product delivery, a full traceability system must be established to record the source, processing parameters, and test results of each batch of boards, enabling rapid identification of the cause in case of problems. For example, if a batch of pallets cracks during use, the traceability system can be used to check the gluing process or moisture content data of the corresponding boards, thereby optimizing subsequent production processes.

The quality stability of fumigation-free wooden pallets requires collaborative efforts across the entire chain, encompassing "source control, process improvement, design optimization, rigorous testing, environmental control, and standardized management." Only by perfecting each step can high-quality pallets be produced that meet both international environmental standards and the stringent requirements of the logistics industry.